Product Description

Hydraulic Slewing Gearbox Planetary Gear Motor Reducer for Truck Crane Tow Truck Wrecker

Product Description

CHUANGXIHU (WEST LAKE) DIS. planetary reducer gearbox is designed with large torque, high start and transmission efficiency, low-speed stability, compact radial size, low noise, etc. The main devices we are making are walking reducers, lifting reducers and swing reducers. They are widely used for vehicle cranes, crawler cranes, truck mounted cranes, marine cranes, aerial work trucks, excavators, etc.

| Product Name | Slewing Drive Planetary Gearbox Reducer |

| Output Torque | 800~100000N.m or customzed |

| Input Speed | 600~2000rpm or customized |

| Output Speed | 1.5~1200rpm or customized |

| Gearing Arrangement | Planetary |

| Customized support | OEM, ODM |

| Package | Professional Ship Pack Wooden Case or do according customer’s request |

| Main Features | 1) Compact size 2) Low noise 3) High transmission efficiency 4) Good working condition under lower speed

5) Customized hydraulic motors and brakes for different request 6) One Year Warranty from reception 9) Free technical support at any time 10) Customer training is available. |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works , Energy & Mining,crane ,etc |

Product Application

Slewing Drive Reducer Application: Widely used in construction, water conservancy engineering, forestry, mining, wharf, etc. material lifting, also can be used as a modern electronic control automatic operation line supporting

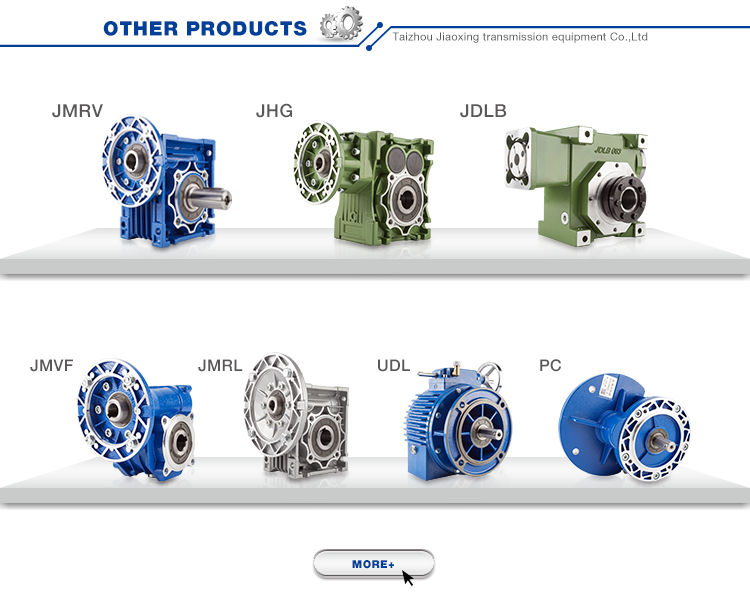

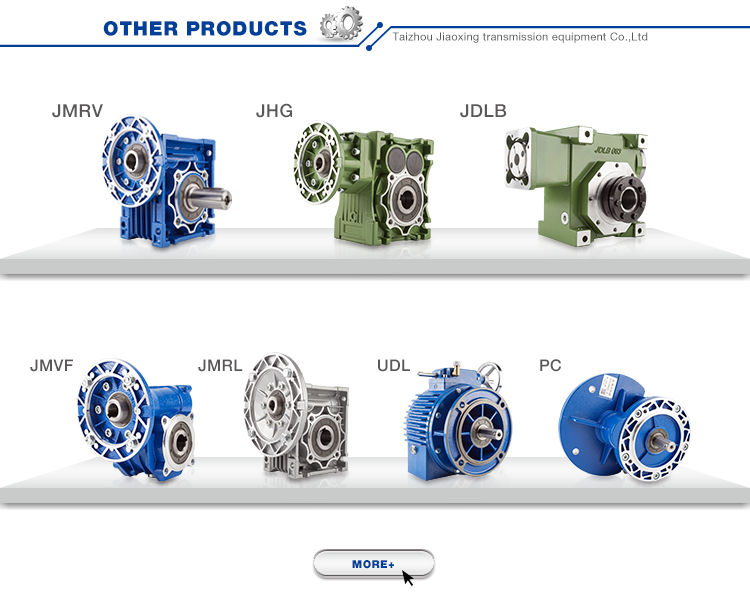

Main Products

Hydraulic Winch Hydraulic Hoist Winch Slewing Drive Reducer

Final Drive Reducer Electric Winch Hydraulic Motor

Our Company

Taian Chuangdong New Material Technology Co., Ltd. is 1 professinal factory has successively developed a series of planetary transmission mechanisms in the fields of lifting machinery, exploration machinery, obstacle clearance machinery, aerial work vehicle machinery , marine machinery, petroleum machinery, and truck mounted cranes. At present, our company main products include 8-100 ton hoisting and slewing mechanisms for truck cranes,16-100 ton walking mechanisms for crawler cranes, 18-30 meter hoisting and slewing mechanisms for aerial work vehicles, 6-25 ton hydraulic winches and slewing mechanisms for truck mounted cranes, and 1.5-30 ton IYJ series hydraulic winches widely used in obstacle clearing machinery, marine machinery, and petroleum machinery.

we hane many business partner ,here some famous company such these :

Mitsubishi Heavy Industries, Ltd.

SA NY HEAVY INDUSTRY CO., LTD.

XC MG Construction Machinery

ZOOMLION/Furukawa Electric Co., Ltd.

We welcome your cooperation.

FAQ

Q1: Are you a factory?

A1: Yes,Of course.

Q2: Can you provide customized products? OEM or ODM products?

A2:Yes,we can provide customized products according to your requirements. Both OEM and ODM are acceptable.

Q3: How about the delivery time?

A3: Delivery time will be within 10-30 workingdays since the PI is confirmed.

Q4: How do you ensure your product and service quality?

A4: We have a series of professional testing devices, and all the production line will strictly supervised by QC. We offer the test report before shipment.

Q5: Can you provide sample?

A5: Yes, we can provide you sample, but you need to pay for the sample and freight firstly.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Marine, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Type: | Planetary Gear Reducer |

| Product Name: | Slewing Drive Planetary Gearbox Gear Speed Reduc |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide real-world examples of products that use gear reducer technology?

Certainly! Gear reducer technology is widely used in various industries and products to enhance performance and efficiency. Here are some real-world examples:

1. Industrial Machinery: Gear reducers are commonly used in manufacturing machinery, such as conveyor systems, material handling equipment, and assembly lines, where they help control speed and torque for precise operations.

2. Wind Turbines: Wind turbines utilize gear reducers to transform the low rotational speed of the wind turbine rotor into the higher speed needed for electricity generation, optimizing energy conversion.

3. Automotive Transmissions: Automobiles use gear reducers as part of their transmissions to optimize power delivery from the engine to the wheels, allowing the vehicle to operate efficiently at different speeds.

4. Robotics: Robotic systems rely on gear reducers to control the movement and articulation of robot arms, enabling precise and controlled motion for various applications.

5. Printing Presses: Gear reducers are integral to printing presses, ensuring accurate and synchronized movement of printing plates, rollers, and paper feed mechanisms.

6. Conveyor Belts: Conveyor systems in industries like mining, agriculture, and logistics use gear reducers to regulate the movement of materials along the conveyor belts.

7. Packaging Machinery: Gear reducers play a crucial role in packaging machines, controlling the speed and movement of packaging materials, filling mechanisms, and sealing components.

8. Cranes and Hoists: Cranes and hoists rely on gear reducers to lift heavy loads with precision and control, ensuring safe and efficient material handling.

9. Pumps and Compressors: Gear reducers are utilized in pumps and compressors to regulate fluid flow and pressure, optimizing energy usage in fluid transportation systems.

10. Agriculture Equipment: Tractors and other agricultural machinery use gear reducers to adjust the speed and power delivery for different tasks, such as plowing, planting, and harvesting.

These examples demonstrate the diverse applications of gear reducer technology across various industries, showcasing their role in enhancing efficiency, control, and performance in a wide range of products and systems.

Can gear reducers be used for both speed reduction and speed increase?

Yes, gear reducers can be utilized for both speed reduction and speed increase, depending on their design and arrangement. The functionality to either decrease or increase rotational speed is achieved by altering the arrangement of gears within the gearbox.

1. Speed Reduction: In speed reduction applications, a gear reducer is designed with gears of different sizes. The input shaft connects to a larger gear, while the output shaft is connected to a smaller gear. As the input shaft rotates, the larger gear turns the smaller gear, resulting in a decrease in output speed compared to the input speed. This configuration provides higher torque output at a lower speed, making it suitable for applications that require increased force or torque.

2. Speed Increase: For speed increase, the gear arrangement is reversed. The input shaft connects to a smaller gear, while the output shaft is connected to a larger gear. As the input shaft rotates, the smaller gear drives the larger gear, resulting in an increase in output speed compared to the input speed. However, the torque output is lower than that of speed reduction configurations.

By choosing the appropriate gear ratios and arrangement, gear reducers can be customized to meet specific speed and torque requirements for various industrial applications. It’s important to select the right type of gear reducer and configure it correctly to achieve the desired speed reduction or speed increase.

How do gear reducers contribute to speed reduction and torque increase?

Gear reducers play a crucial role in mechanical systems by achieving speed reduction and torque increase through the principle of gear ratios. Here’s how they work:

Gear reducers consist of multiple gears with different sizes, known as gear pairs. These gears are meshed together, and their teeth interlock to transmit motion and power. The gear ratio is determined by the ratio of the number of teeth on the input gear (driver) to the number of teeth on the output gear (driven).

Speed Reduction: When a larger gear (output gear) is driven by a smaller gear (input gear), the output gear rotates at a slower speed than the input gear. This reduction in speed is proportional to the gear ratio. As a result, gear reducers are used to slow down the rotational speed of the output shaft compared to the input shaft.

Torque Increase: The interlocking teeth of gears create a mechanical advantage that allows gear reducers to increase torque output. When the input gear applies a force (torque) to the teeth, it is transmitted to the output gear with greater force due to the leverage provided by the larger diameter of the output gear. The torque increase is inversely proportional to the gear ratio and is essential for applications requiring high torque at lower speeds.

By selecting appropriate gear ratios and arranging gear pairs, gear reducers can achieve various speed reduction and torque multiplication factors, making them essential components in machinery and equipment where precise control of speed and torque is necessary.

editor by CX 2024-04-16

China best Wholesale Concrete Pump Mixer Truck Hydraulic Axial Plunger Piston Pump Motor Repair Kits Spare Parts PMP PMP6.0 PMP6.5 PMP7.1 PMP7.8 Gear Box Reduction Reducer gearbox drive shaft

Product Description

Product Description

Wholesale Concrete Pump Mixer Truck Hydraulic Axial Plunger Piston Pump motor Repair Kits Spare Parts PMP PMP6.0 PMP6.5 PMP7.1 PMP7.8 gear box reduction reducer

Detailed Photos

Product Parameters

| Product name | reducer |

| Model number | PMP PMP6.0 PMP6.5 PMP7.1 PMP7.8 |

| Color | As the picture shows |

| Size | Standard |

| Material | Iron |

| Package | Carton box/ Wooden box |

| MOQ | 1/SET |

| Application field | Construction machinery |

Similar product

Company Profile

HangZhou HangZhoung Hydraulic Co.,Ltd was established in August of 2004, which is locate Xihu (West Lake) Dis. town of Xihu (West Lake) Dis. District, HangZhou.

The company is famous for R&D, production, manufacturing full ranges hydraulic pump components, which are widely used on road machineries, constructions industries and Industrial Machinery Industry.

Our technology department have strong product design, developing and productions capabilities to satisfied market need, meanwhile, our supplying hydraulic components enjoy a high reputation in the market with advanced technology, excellent quality, comprehensive services and complete specifications. , exactly matches the needs of customers at different solution plans.

Company philosophy

The company’s products are based in the industry with quality, complete varieties, bulk export, and affordable prices, and adhere to the business philosophy of “customer first, forge ahead”.

Company purpose

Adhere to the “customer first, service first,develop an enterprise with quality, win with excellence” principle to provide our customers with quality services.

Exhibition show

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q:How long has your company run in Hydraulic Fields?

A:More than 15years.

Q:IS your company accept customization?

A:We could accept OEM depends on quantity.

Q: What is your terms of payment ?

A:L/C T/T D/A D/P Western Union

If you have another question, pls feel free to contact us.

| After-sales Service: | Online Service |

|---|---|

| Warranty: | Standard |

| Mesh Form: | Standard |

| Tooth Flank: | Standard |

| Tooth Curve: | Standard |

| Power: | Hydraulic |

| Samples: |

US$ 110/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide real-world examples of products that use gear reducer technology?

Certainly! Gear reducer technology is widely used in various industries and products to enhance performance and efficiency. Here are some real-world examples:

1. Industrial Machinery: Gear reducers are commonly used in manufacturing machinery, such as conveyor systems, material handling equipment, and assembly lines, where they help control speed and torque for precise operations.

2. Wind Turbines: Wind turbines utilize gear reducers to transform the low rotational speed of the wind turbine rotor into the higher speed needed for electricity generation, optimizing energy conversion.

3. Automotive Transmissions: Automobiles use gear reducers as part of their transmissions to optimize power delivery from the engine to the wheels, allowing the vehicle to operate efficiently at different speeds.

4. Robotics: Robotic systems rely on gear reducers to control the movement and articulation of robot arms, enabling precise and controlled motion for various applications.

5. Printing Presses: Gear reducers are integral to printing presses, ensuring accurate and synchronized movement of printing plates, rollers, and paper feed mechanisms.

6. Conveyor Belts: Conveyor systems in industries like mining, agriculture, and logistics use gear reducers to regulate the movement of materials along the conveyor belts.

7. Packaging Machinery: Gear reducers play a crucial role in packaging machines, controlling the speed and movement of packaging materials, filling mechanisms, and sealing components.

8. Cranes and Hoists: Cranes and hoists rely on gear reducers to lift heavy loads with precision and control, ensuring safe and efficient material handling.

9. Pumps and Compressors: Gear reducers are utilized in pumps and compressors to regulate fluid flow and pressure, optimizing energy usage in fluid transportation systems.

10. Agriculture Equipment: Tractors and other agricultural machinery use gear reducers to adjust the speed and power delivery for different tasks, such as plowing, planting, and harvesting.

These examples demonstrate the diverse applications of gear reducer technology across various industries, showcasing their role in enhancing efficiency, control, and performance in a wide range of products and systems.

What role do gear ratios play in optimizing the performance of gear reducers?

Gear ratios play a crucial role in optimizing the performance of gear reducers by determining the relationship between input and output speeds and torques. A gear ratio is the ratio of the number of teeth between two meshing gears, and it directly influences the mechanical advantage and efficiency of the gear reducer.

1. Speed and Torque Conversion: Gear ratios allow gear reducers to convert rotational speed and torque according to the needs of a specific application. By selecting appropriate gear ratios, gear reducers can either reduce speed while increasing torque (speed reduction) or increase speed while decreasing torque (speed increase).

2. Mechanical Advantage: Gear reducers leverage gear ratios to provide mechanical advantage. In speed reduction configurations, a higher gear ratio results in a greater mechanical advantage, allowing the output shaft to deliver higher torque at a lower speed. This is beneficial for applications requiring increased force or torque, such as heavy machinery or conveyor systems.

3. Efficiency: Optimal gear ratios contribute to higher efficiency in gear reducers. By distributing the load across multiple gear teeth, gear reducers with suitable gear ratios minimize stress and wear on individual gear teeth, leading to improved overall efficiency and prolonged lifespan.

4. Speed Matching: Gear ratios enable gear reducers to match the rotational speeds of input and output shafts. This is crucial in applications where precise speed synchronization is required, such as in conveyors, robotics, and manufacturing processes.

When selecting gear ratios for a gear reducer, it’s important to consider the specific requirements of the application, including desired speed, torque, efficiency, and mechanical advantage. Properly chosen gear ratios enhance the overall performance and reliability of gear reducers in a wide range of industrial and mechanical systems.

How do gear reducers handle variations in input and output speeds?

Gear reducers are designed to handle variations in input and output speeds through the use of different gear ratios and configurations. They achieve this by utilizing intermeshing gears of varying sizes to transmit torque and control rotational speed.

The basic principle involves connecting two or more gears with different numbers of teeth. When a larger gear (driving gear) engages with a smaller gear (driven gear), the rotational speed of the driven gear decreases while the torque increases. This reduction in speed and increase in torque enable gear reducers to efficiently adapt to variations in input and output speeds.

The gear ratio is a critical factor in determining how much the speed and torque change. It is calculated by dividing the number of teeth on the driven gear by the number of teeth on the driving gear. A higher gear ratio results in a greater reduction in speed and a proportionate increase in torque.

Planetary gear reducers, a common type, use a combination of gears including sun gears, planet gears, and ring gears to achieve different speed reductions and torque enhancements. This design provides versatility in handling variations in speed and torque requirements.

In summary, gear reducers handle variations in input and output speeds by using specific gear ratios and gear arrangements that enable them to efficiently transmit power and control motion characteristics according to the application’s needs.

editor by CX 2023-12-08

China Best Sales AC Hydraulic Motor Gear Reducer for Drilling Rig Concrete Mixer with Good quality

Product Description

Product Description:AC hydraulic Motor gear reducer for drilling rig concrete mixer

AC Motor is a device that transforms the electrical energy of alternating current into mechanical energy. The AC Motor is mainly composed of an electromagnet winding or stator winding for generating magnetic field and a rotating armature or rotor. The motor is made by the phenomenon that the electric coil is forced to rotate in the magnetic field. AC motors are divided into 2 types: synchronous alternating current motor and induction motor.

The stator windings of three-phase AC motors are basically 3 coils separated by 120 degrees, which are connected by triangle or star. When three-phase current is applied, a magnetic field is generated in each coil, and the 3 magnetic fields are combined to form a rotating magnetic field.

High voltage ac motors are designed with the application of modern technology resulting in compact machines featuring excellent dynamic properties, meeting the most severe application in areas that include automation and process control.

Besides offering reliability and high performance, which will guarantee long operating periods without requiring any maintenance, the New high voltage ac motors present outstanding operating features, which include:

•Wide speed variation range

•Dimensions as per GB and IEC Standards

•High efficiency

•Low noise level

•High moment of inertia

•High capacity to dynamic loads

•Rugged construction

•High vibration resistance

•Excellent commutation quality

Product Parameters:

| Product Name | AC hydraulic Motor gear reducer for drilling rig concrete mixer |

| Motor Type | DC Motor,AC Motor,Stepper Motor,Asynchronous Motor ,Synchronous Motor (Electric machinery) |

| Rotational Speed |

Low Speed/Constant Speed/High Speed/Variable Speed |

| Stator Phase Number |

Three-Phase/Single-Phase |

| Standard Features | •NEMA Premium Efficiency Level according to NEMA Y •Three-phase, 50, 60 Hz •Voltage: 3000 to 11000 V •Rated output: up to 12500 kw •Number of poles: 2 ,4,6,8,10 or 12poles •Frame sizes: 450 mm to 630mm •Cast aluminium squirrel cage for rotor •Degree of protection: IP23 to IP54(Totally enclosed) •Class insulation F with class (120ºC) temperature rise •Grease nipples for frame 450 to 630MM •Continuous Duty (S1) •With thermal protection PTC140 ºC or PT100 •Larger diameter shafts for the highest overhung load ratings in the industry •Oversized roller bearings for maximum load capacity •Other optional features under request |

| AC Motor | AC Motors can operate in high temperature, flammable and other environments, and do not need to clean the dirt of carbon brushes regularly, but it is difficult to control the speed, because it is necessary to control the frequency of AC motors (or use induction motors, increase internal resistance, reduce the motor speed at the same AC frequency. Speed, control the voltage will only affect the torque of the motor. The voltage of the general civil motor has 2 kinds, such as 110V and 220V, and there are 380V or 440V in industrial application. |

| Application | AC Motors have higher working efficiency, no smoke, odor, no pollution to the environment, and less noise. Because of its series of advantages, it is widely used in industrial and agricultural production, transportation, national defense, commercial and household appliances, medical appliances and other fields. For Example: •Compressor •Rubber mixer •Fans and Pumps •Air brower •Coal mill and rolling mill •Crushers •Conveyor belts •Centrifugal machines •Lathe •Hoist |

Product Show

| Application: | Industrial |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Closed Type |

| Number of Poles: | 2 |

| Customization: |

Available

| Customized Request |

|---|

How do gear reducers ensure efficient power transmission and motion control?

Gear reducers play a vital role in ensuring efficient power transmission and precise motion control in various industrial applications. They achieve this through the following mechanisms:

- 1. Speed Reduction/Increase: Gear reducers allow you to adjust the speed between

How do manufacturers ensure the precision of gear tooth profiles in gear reducers?

Manufacturers employ several techniques to ensure the precision of gear tooth profiles in gear reducers, which is crucial for optimal performance and efficiency:

1. Precision Machining: Gear teeth are typically machined using advanced CNC (Computer Numerical Control) machines that can achieve high levels of accuracy and repeatability. This ensures consistent gear tooth profiles across multiple components.

2. Quality Control Measures: Rigorous quality control processes, such as dimensional inspections and profile measurements, are performed at various stages of manufacturing to verify that gear tooth profiles meet the required specifications.

3. Tooth Profile Design: Engineers use specialized software and simulation tools to design gear tooth profiles with precise involute shapes and accurate dimensions. These designs are then translated into machine instructions for manufacturing.

4. Material Selection: High-quality materials with excellent wear resistance and dimensional stability are chosen to minimize the potential for deformation or inaccuracies during machining and operation.

5. Heat Treatment: Heat treatment processes, such as carburizing and quenching, are applied to enhance the surface hardness and durability of gear teeth, reducing the risk of wear and deformation over time.

6. Tooth Grinding and Finishing: After initial machining, gear teeth often undergo precision grinding and finishing processes to achieve the desired tooth profile accuracy and surface finish.

7. Post-Processing Inspection: Gear tooth profiles are inspected again after manufacturing processes to verify that the final components meet the specified tolerances and performance criteria.

8. Computer-Aided Manufacturing (CAM): CAM software is used to generate tool paths and machining instructions, enabling precise control over tool movements and material removal during gear manufacturing.

By combining these techniques and leveraging advanced manufacturing technologies, manufacturers can achieve the necessary precision in gear tooth profiles, resulting in reliable and efficient gear reducers for various industrial applications.

the input and output shafts. Speed reduction is essential when the output speed needs to be lower than the input speed, while speed increase is used when the opposite is required.

- 2. Torque Amplification: By altering the gear ratio, gear reducers can amplify torque from the input to the output shaft. This enables machinery to handle higher loads and provide the necessary force for various tasks.

- 3. Gear Train Efficiency: Well-designed gear trains within reducers minimize power losses during transmission. Helical and spur gears, for example, offer high efficiency by distributing load and reducing friction.

- 4. Precision Motion Control: Gear reducers provide precise control over rotational motion. This is crucial in applications where accurate positioning, synchronization, or timing is required, such as in robotics, CNC machines, and conveyor systems.

- 5. Backlash Reduction: Some gear reducers are designed to minimize backlash, which is the play between gear teeth. This reduction in play ensures smoother operation, improved accuracy, and better control.

- 6. Load Distribution: Gear reducers distribute the load evenly among multiple gear teeth, reducing wear and extending the lifespan of the components.

- 7. Shock Absorption: In applications where sudden starts, stops, or changes in direction occur, gear reducers help absorb and dampen shocks, protecting the machinery and ensuring reliable operation.

- 8. Compact Design: Gear reducers provide a compact solution for achieving specific speed and torque requirements, allowing for space-saving integration into machinery.

By combining these principles, gear reducers facilitate the efficient and controlled transfer of power, enabling machinery to perform tasks accurately, reliably, and with the required force, making them essential components in a wide range of industries.

How do gear reducers handle variations in input and output speeds?

Gear reducers are designed to handle variations in input and output speeds through the use of different gear ratios and configurations. They achieve this by utilizing intermeshing gears of varying sizes to transmit torque and control rotational speed.

The basic principle involves connecting two or more gears with different numbers of teeth. When a larger gear (driving gear) engages with a smaller gear (driven gear), the rotational speed of the driven gear decreases while the torque increases. This reduction in speed and increase in torque enable gear reducers to efficiently adapt to variations in input and output speeds.

The gear ratio is a critical factor in determining how much the speed and torque change. It is calculated by dividing the number of teeth on the driven gear by the number of teeth on the driving gear. A higher gear ratio results in a greater reduction in speed and a proportionate increase in torque.

Planetary gear reducers, a common type, use a combination of gears including sun gears, planet gears, and ring gears to achieve different speed reductions and torque enhancements. This design provides versatility in handling variations in speed and torque requirements.

In summary, gear reducers handle variations in input and output speeds by using specific gear ratios and gear arrangements that enable them to efficiently transmit power and control motion characteristics according to the application’s needs.

editor by CX 2023-09-01

China Custom China Professional S Series Hydraulic Motor Gear Reducer with Good quality

Merchandise Description

Product Description

Solution Features

Higher modular layout, biomimetic surface area with owned intellectual property right.

Undertake German worm hob to procedure the worm wheel.

With the unique gear geometry, it receives higher torque, performance and prolonged life circle.

It can attain the direct combination for 2 sets of gearbox.

Mounting mode: foot mounted, flange mounted, torque arm mounted.

Output shaft: strong shaft, hollow shaft.

Main applied for

Chemical industry and environmental safety

Metallic processing

Developing and construction

Agriculture and foods

Textile and leather-based

Forest and paper

Car washing machinery

Comprehensive Photographs

Merchandise Parameters

Complex information:

|

Housing content |

Forged iron/Ductile iron |

|

Housing hardness |

HBS190-240 |

|

Gear content |

20CrMnTi alloy metal |

|

Surface area hardness of gears |

HRC58°~62 ° |

|

Gear core hardness |

HRC33~forty |

|

Enter / Output shaft content |

42CrMo alloy metal |

|

Input / Output shaft hardness |

HRC25~30 |

|

Machining precision of gears |

exact grinding, 6~5 Grade |

|

Lubricating oil |

GB L-CKC220-460, Shell Omala220-460 |

|

Warmth remedy |

tempering, cementiting, quenching, and many others. |

|

Effectiveness |

ninety four%~96% (relies upon on the transmission phase) |

|

Sounds (MAX) |

sixty~68dB |

|

Temp. rise (MAX) |

40°C |

|

Temp. increase (Oil)(MAX) |

50°C |

|

Vibration |

≤20µm |

|

Backlash |

≤20Arcmin |

|

Brand of bearings |

China top manufacturer bearing, HRB/LYC/ZWZ/C&U. Or other brand names asked for, SKF, FAG, INA, NSK. |

|

Brand name of oil seal |

NAK — ZheJiang or other brands asked for |

Our Positive aspects

Certifications

Packaging & Delivery

Business Profile

Xihu (West Lake) Dis.ng Transmission Equipment Co., Ltd. situated HangZhou metropolis, ZHangZhoug, as 1 skilled manufacturer and exporter of cycloidal pin wheel reducer,worm reducer, gear reducer, gearbox , AC motor and relative spare components, owns prosperous expertise in this line for a lot of many years.

We are 1 immediate manufacturing unit, with innovative manufacturing equipment, the strong improvement staff and producing capability to offer good quality products for buyers.

Our items commonly served to a variety of industries of Metallurgy, Chemical compounds, lifting,mining,Petroleum,textile,medication,wooden etc. Main markets: China, Africa,Australia,Vietnam, Turkey,Japan, Korea, Philippines…

Welcome to inquire us any questions, very good offer usually for you for extended phrase organization.

FAQ

Q: Are you trading organization or producer?

A: We are manufacturing unit.

Q: How prolonged is your delivery time?

A: Usually it is 5-ten times if the goods are in stock. or it is 15-20 times if the merchandise are not in inventory.

Q: Can we get 1 computer of every single product for quality tests?

A: Indeed, we are happy to accept demo purchase for quality testing.

Q:How to decide on a gearbox which meets your prerequisite?

A:You can refer to our catalogue to choose the gearbox or we can aid to select when you give

the complex info of necessary output torque, output speed and motor parameter etc.

Q: What data shall we give before positioning a acquire get?

A:a) Kind of the gearbox, ratio, input and output sort, input flange, mounting place, and motor informationetc.

b) Housing coloration.

c) Obtain quantity.

d) Other particular specifications.

We are experienced transmission dealers and offer you a broad range of transmissions, an important part of numerous push techniques. Gearboxes can be utilized to decrease or increase pace, increase torque, reverse or modify the route of a generate shaft. Gearboxes are also acknowledged as equipment drives, velocity reducers, gear motors, speed reducers and gear reducers.

These compact, light-weight, minimal backlash inline equipment reducers have been initially created for encoder purposes. They are also suitable for a lot of other travel techniques. Encoder gear reducers have a quite low moment of inertia at the shaft input and are rated for enter speeds up to 3000 rpm. Two frame sizes are offered with equipment ratios from 4.ninety six:1 to 3600:1. Our encoder gearbox sync pads are obtainable from stock.

in Novosibirsk Russian Federation sales price shop near me near me shop factory supplier Varitron Cyclo Drive Gear Box Speed Reducer Motor Hydraulic Variator manufacturer best Cost Custom Cheap wholesaler

Support & High quality controlWe source in depth drawings and supply anytime required. Our merchandise are used in numerous fields. Much more importantly, we make particular parts in accordance to provided drawings/samples and warmly welcome OEM inquiries. Varitron Cyclo Generate Equipment box Velocity EPT EPT EPT variator

1 periodProduct features

1 period1 periodJWB-X sequence higher precision velocity variator with foot mounted and flange mounted

one period2 periodCan be merged with other kinds of EPTes lparSuch as R Series comma K Collection comma F Collection comma S Series comma NMRV Sequence EPT rpar

1 period3 period of time Input EPT colon0 period18KW-seven period5KW

1 period4 interval Compact composition commahigh depth and EPT serving time

one period5 interval num1- num4 EPT housing and num5- num6 cast iron housing

1 period6 period of time Max output speed to min output speed is five colon1

one period7 period Repeatedly workable comma bidirectional working course commasmooth managing commastable comma and quiet

2 time period EPT parameters

| Model | JWB-X Sequence |

| Base No interval | 01-04 num |

| Hues | Blue or OEM hues |

| Input EPT | period18-seven period5KW |

| Output Speed | one hundred ninety-950rpm |

| Output Torque | 11-five period4Nm |

| Maint parts | EPTr commapress ring commaplanet wheel commafixed ring commaspeed management cam commafixed cam |

| Maint components substance | GCr15 |

| Lubrication | Ub-three |

3 periodApplications

HangEPT XG EPT EPT EPT are broadly utilised in colon

Ceramic Market

Glass Market

Foods Industry

EPTlurgy Business

Beer amp Consume Business

EPT and dyeing Industry

Textile Sector

Warehouse Logoistics Business

EPT doing work EPTry

environmental safety equipment Business

Leather Sector

Pharmacy Sector

4 periodOur Solutions

four period1 periodWe supply twelve months Guarantee period of time

four period2 time period We have thousands of EPT EPTs period From Input EPT period06KW to 200KW comma Ratio one period3-289 period74 comma Output pace -1095rpm and Output torque one period4-62800Nm interval interval periodThey can fulfill your all various specifications for distinct EPT interval

4 period3 time period We provide E-catalog or Paper catalog commaso you can pick the model simply in accordance to your specifications

four period4 periodYou are welcome to check out our manufacturing unit to verify our products commawe can aid you to guide the hotel or ticket

five periodCompany Information

5 period1 periodOur Organization colon

The Predecessor for ZheJiang EPT Travel CO interval commaLtd lparoriginally referred to as HangEPT XiHu (West Lake) Dis.ngguang EPT EPTry CO interval commaLtd rpar Condition-owned military mould EPTrpriese which estabEPTd in 1965 interval

EPT is found in HangEPT commaEPT and the factory handles an region of about 25000 square meters interval

Production Potential colonmore than fifty percent a million sets of pace EPT per 12 months interval

five period2 periodOur Folks colon

The organization has a sturdy specialized power period of time It has much more than 400 employees at existing comma incXiHu (West Lake) Dis.Hu (West Lake) Dis. much more than forty engineering professionals and 10 authorities and senior engineers enEPTing EPT allowances of the State Council time period

five period3 time period Our Certificates colon

Passed quot ISO 9001 Intercontinental EPT Technique Certification quot comma quotInternational EPT Credit history AAA in addition in addition Ceritifacte quot comma quot Swiss SGS Certificate quot comma Legendary Model in EPT EPT Industry quot comma quotFamous Brand name of ZheJiang Province quot comma quotNon-public Scientific and Technological EPTrprise in ZheJiang Province quot comma quotNational Large and EPT-tech EPTrprise quot comma quotTOP 50 in EPT Equipment Industry quot quot2011 HangEPT Engineering and Technological R ampD CEPTr quot and so on period

6 period of time FAQ

Q colonAre you a trading business or producer quest

A colon The predecessor of HangEPT XG-EPT EPTry Co period comma Ltd is Condition-owned XiHu (West Lake) Dis.ngguanggong Mildew Manufacturing unit comma a condition-owned armed forces EPT EPTrprise estabEPTd in 1965 time period It finished reform in 2002 period of time Considering that reform comma EPT has deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ed rapidly period It took the direct in passing ISO9001 Global EPT System Certification and Worldwide EPT Credit score AAA plus plus Certification in 2004 comma and Swiss SGS Certification in 2009 time period It has gained these kinds of titles as quotIconic Brand name in EPT EPT Market quot comma quotFamous Brand of ZheJiang Province quot comma quotNon-general public Scientific and Technological EPTrprise in ZheJiang Province quot comma quotNational Higher and EPT-tech EPTrprise quot comma and quotTope fifty in EPT Gear Market quot successively

Q colonWhere do you base quest

A colon We are in HangEPT commaZheJiang commaEPT interval We have two factories commaEPT manufacturing facility is in XiHu (West Lake) Dis.hu (West Lake) Dis. district commaHangEPT commaEPT and the outdated one is in CHangEPT District commaHangEPT commaEPT period

Q colonWhat types of EPT can you make for us quest

A colonMain items of our company colon JWB-X sequence mechanical continually variable EPT comma RV collection worm EPT EPT comma B solJXJ cycloidal pin EPT velocity EPT comma NCJ sequence EPT EPT comma and R comma S comma K comma and F collection helical-tooth EPT comma far more than 1 hundred versions and countless numbers of specifications period of time

Q colonWhat are the application of the EPT quest

A colonEPT are commonly employed in ceramic comma EPT comma foods comma metallurgy comma beer amp drink comma printing and dyeing comma textile comma petrochemical engineering comma warehouse EPT comma wooden-operating EPT comma environmental protection equipment comma printing and EPT comma pharmacy comma and leather-based period of time EPT are marketed in some nations around the world and regions comma such as Europe comma The united states comma and SouthEPT Asia comma and it possesses dozens of distributors and after-sale service agents period

Q colonWhat is the materials you use quest

A colon EPT situation lpar For the RV sequence worm EPT commamodel RV030-one hundred and five rpar

Cast iron lparFor the RV sequence worm EPT comma design RV110-150 comma For the NCJ solF solR solS solK sequence helical EPT EPT rpar

in Rabat Morocco sales price shop near me near me shop factory supplier Elevator Speed Reducer Gear Motor Worm Electrical Dual Evehicle Greenhouse DC Shaft Geared Hydraulic Electric Motorcycle Cycloidal Reducer Geared Helical Mini manufacturer best Cost Custom Cheap wholesaler

PersonnelOur income folks are well educated to accommodate your requests and talk English for your usefulness. focus in electricity transmission items, CATV goods, mechanical seal, hydraulic and Pheumatic, and advertising goods. The team has taken part in the producing and revising of ISO/TC100 international chain standard several a long time in good results and hosted the 16th ISO/TC100 International annual meeting in 2004. EPT Description

EP169 Building

ELEVATOR Pace EPT

Merchandise Attributes

EPT precision of EPT pairs are up to 5~6 grade.

EPT lubrication to avert leakage successfully.

Computer modification EPT for EPT tooth to improve the carrying ability of EPT pair and reduce sounds.

FEA evaluation software program for optimization of housing design and style, assure power and stiffness, also increase shaft power and bearing lifestyle.EPT is produced by ductile iron, it’s useful to sturdy composition, sound and vibration dampening.

Hint FOR Consumers:

one. When environmental temperature is unEPTthan -five degC, it is essential to use artificial oil.

two. The dimensions and technical specs are matter to change with out observe.

| Swift Reply | All enquiry or email be replied in twelve several hours, no hold off for your company. |

| Specialist Staff | Queries about goods will be replied skillfully, just, greatest advice to you. |

| Quick EPT time | Sample or tiny orEPTsent in seven-fifteen days, bulk or customized orEPTabout 30 times. |

| Payment Choice | T/T, Western Union,, L/C, and so on, straightforward for your company. |

| Just before shipment | EPTke pictures, deliver to customers for confirmation. Only verified, can be transported out. |

| Language Choice | Aside from EPT, you can use your own language by e mail, then we can translate it. |

Best China manufacturer & factory High in Orenburg Russian Federation quality small hydraulic ac gear reducer motor With high quality best price

Additionally, WE CAN Produce Tailored VARIATORS, GEARED MOTORS, Electrical MOTORS AND OTHER HYDRAULIC Merchandise According TO CUSTOMERS’ DRAWINGS.

Overview

Swift Particulars

To get rid of get in touch with-pattIf you are seeking for a 540 PTO shaft, 540 to one thousand PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, look no more. It is important to exchange PTO areas that are worn or cracking prior to you have a key breakdown that could be costly and even harmful. We have PTO push shafts as properly as crucial shield areas for your basic safety. Our Eurocardan areas include a assortment of sorts of clutches to enhance the operation of your energy consider-off method. PTO shafts and components are an essential portion of the much more than 26,000 things we carry for farm, shop, property and backyard.ern inconsistencies, EPT developed an automated centering device that correctly measures each worm and gear subassembly, as well as the reducer housing and bearing handles. A pc records the information and calculates the thickness and area of shims needed to precisely middle the equipment beneath the worm shaft and, at the exact same time, provides the proper stop 1play for the output tapered-roller bearings. This maximizes operating performance and minimizes temperature rise.

- Applicable Industries:

-

Production Plant

EPG manufacturer rotocultivator ploughshares in T. line ended up chosen as the Nationwide Rotary Tillage Equipment Market “Best Manufacturer Items” in 2007 by Rotocultivator Branch of China Agricultural Machinery Industry Association.

- Gearing Arrangement:

-

worm

- Output Torque:

-

two hundred~915Nm

- Input Velocity:

-

900~2800/min

- Output Pace:

-

eleven.3~35.1/min

- Area of Origin:Zhejiang, China

- Brand name Title:

-

OEM

- Merchandise identify:

-

little hydraulic ac gear reducer motor

- Application:

-

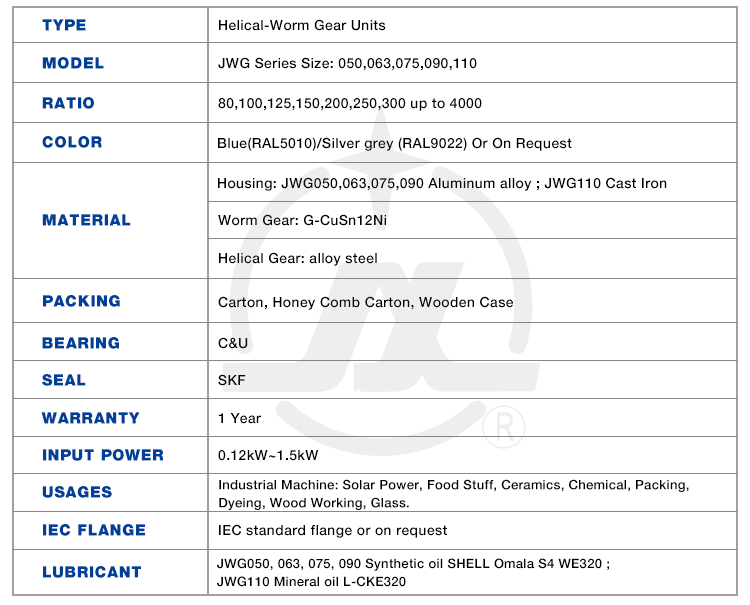

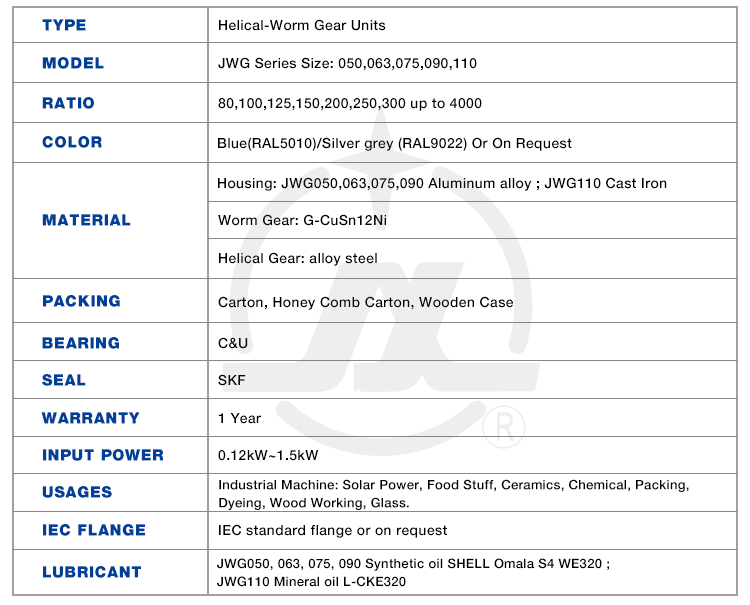

Solar Electrical power, Foods Things, Ceramics, Chemical, Packing, Dyeing, and so forth

- Color:

-

Blue(RAL5010)/Silver grey (RAL9022) Or On Ask for

- Ratio:

-

80,one hundred,125,a hundred and fifty,two hundred,250,three hundred up to 4000

- Guarantee:

-

one Calendar year

Source Potential

- Source Potential:

- 36000 Piece/Items for every Thirty day period

Packaging & Shipping

- Packaging Specifics

- Transparent box packaging, or shade box packaging, it also can be tailored.

- Port

- Ningbo/Shanghai

On-line Customization

High quality little hydraulic ac equipment reducer motor

Q1. How to decide on a worm gearbox which meets our necessity?

A1: You can refer to our catalogue to pick the gearbox or we can support to pick when you offer

the technical details of output torque, output speed and motor parameter etc.

Q2. How is your cost? Can you provide any low cost?

A2: We will give the best value we can foundation on your needs and the portions.

Q3. Do you supply any visiting?

A3: Of course! We sincerely invite you to go to us! We can pick you from airport, railway station and so on.

Also, we can organize housing for you. Make sure you permit us know in innovative.

This fall. When is the very best time to speak to you?

A4: You can speak to us by electronic mail any time, we will reply you as quickly as feasible.

Q5. How long will it just take for the lead time?

A5: For our standard design, please refer to the diverse solution internet pages to examine the guide time.

For the OEM/ODM goods, make sure you contact us for additional information.